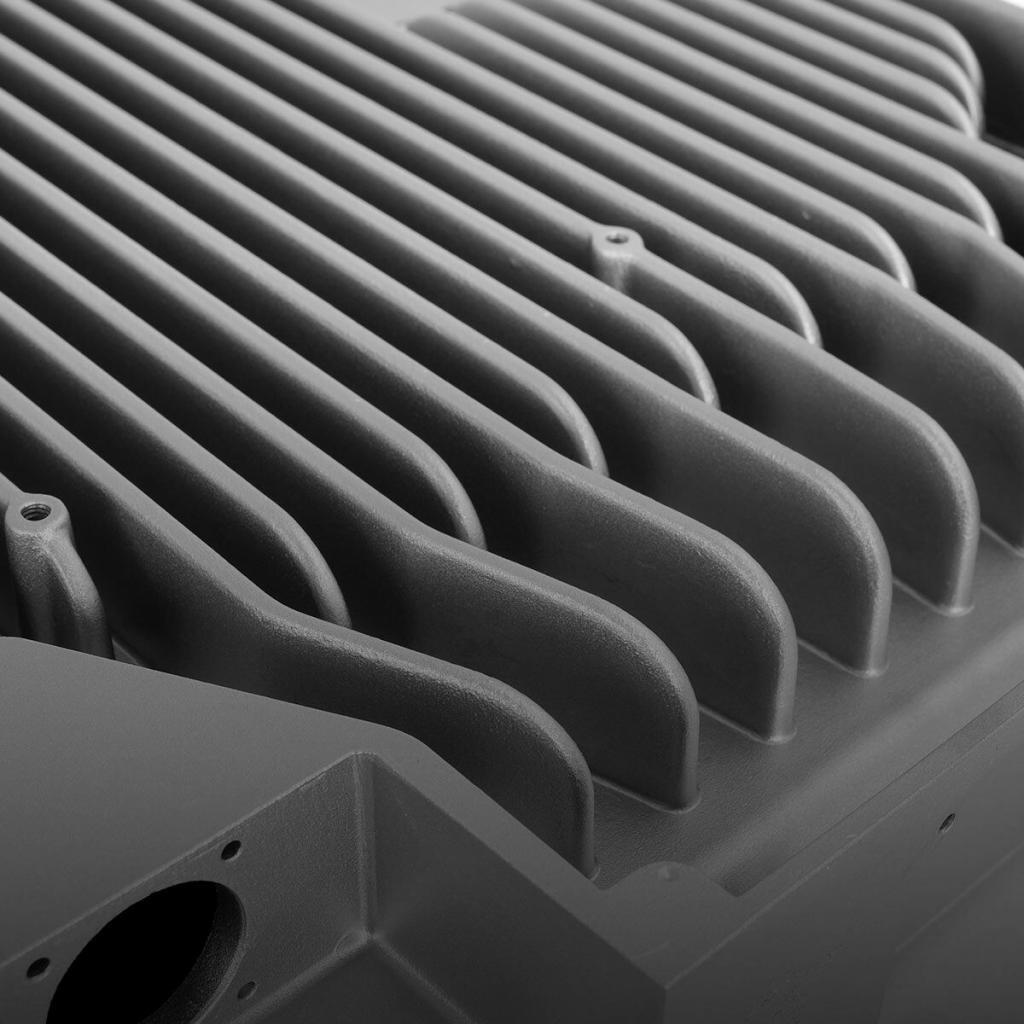

ALUMINUM HIGH PRESSURE DIE CASTING and MOLDING

Aluminium high pressure die casting, which features the process of injecting aluminium material into a mould under high pressure, is another way of describing the pouring of aluminium material into the spaces within the mould. Despite the fact that the process appears consist simply of aluminium poured into a mould, much preparation and preliminary work is required prior to implementation of this process. To illustrate this, the first phase initiated is a 2D or 3D model of the product to be produced at the R&D and Project phase.

Next, prototypes of the designed model are created in the Moulding Room. After selecting the correct materials, the process continues with the Melting of the Aluminium delivered at high temperatures culminating at the casting furnaces. After CNC processing as well as Other Surface Treatments, the process concludes with the final product testing for consistency and durability. The Kalkancı Die Casting Moulding team has the ability to execute the entire process in-house, providing a turnkey service to our valued customers.

OUR ALUMINUM HIGH PRESSURE CASTING CAPABILITIES

Here at KALKANCI, we are able to provide services to different sectors for Aluminium High Pressure Casting and we are constantly developing and improving our systems at our own on-site R&D Laboratory. We are particularly confident and proud of our ability to produce impeccable works at our Moulding Room, ensuring that our choice of materials, which is the most important element of successful production, is meticulous. In addition, we can provide Melting, Casting, CNC processing and other Surface Treatments professionally within our existing infrastructure.

R&D and Project

We constantly strive to improve ourselves with our R&D efforts to increase our Aluminium Casting service capabilities.

Moulding Room

Since 1981, we have been providing professional services in the specialist area of Mould Making for Aluminium Casting products.

Materials

We use standard materials such as EN AC 46000, 44300, 47100, 43400 and specialist materials such as EN AC 43500 and 51500 in our Aluminium Casting production line.

Melting

With our 5 main melting furnaces, we can meet any kind of requirement and orders for Aluminium Casting.

QUALITY

Kalkancı Die Casting Moulding has the capacity to offer services to different sectors in Aluminium High Pressure Casting moulds. Providing services in different areas has advantages and it also increases the responsibility taken for quality and control. Our in-house Quality and Inspection phases are applied as follows: X-Ray Inspection Compression Test, Materials Analysis, Surface Roughness Test, Microscopic Inspection, CMMMeasurement and Gauge/Visual Inspection.

X-Ray Inspections

X-Ray inspections, which constitute the first control leg of our Aluminium Casting production, are carried out with a YXLON X-Ray machine.

Compression Testing

Here at KALKANCI, we apply the most rigorous tests to our products, conducting Compression Tests in our Aluminium Casting production.

Materials Analysis

We perform analyses of materials used in our Aluminium Casting production with a range of devices including Zeiss, Spectromax, ZwickNikon, Affri and Mitutoyo.

Microscope Testing

We to check for competence, quality and durability in our Aluminium Casting production by conducting microscope testing.

SECTORS

Kalkancı Die Casting Moulding provides services in the energy, electronics, automotive and lighting industries, together the most vital global sectors today, meeting our customer’s needs and demands for Aluminium High Pressure Casting with the utmost professionalism. We are keenly aware that different sectors have different needs and expectations. For this reason, we integrate technological innovation for the sectors we serve into our in-house processes and develop our R&D research using a holistic approach.

Energy

We undertake the production and manufacturing of Aluminium Casting parts for the energy sector, noting that energy is the most important requirement today.

Automotive

We serve the automotive sector with any and all diverse Aluminium Casting parts produced with great professionalism.

Electronic

We produce AluminiumDie Casting parts for the Electronics industry, another key sector in the growing and globalising world.

Lighting

We produce all kinds of Aluminium Die Casting parts to meet the demands of the lighting industry.

SOME BRANDS THAT PREFER OUR PRODUCTS AND SERVICES

KALKANCI has serviced and continues to serve dozens of brands due to its global standard of service. We are proud to present our references from customers that rely on KALKANCI and benefit from our professional services.